Flexible service thanks to portable balancing devices

Mobile balancing - directly on site

With Ibis you achieve smooth running for your machine operation. Benefit from our balancing service so that machines and systems can operate smoothly and efficiently.

Solved quickly and competently

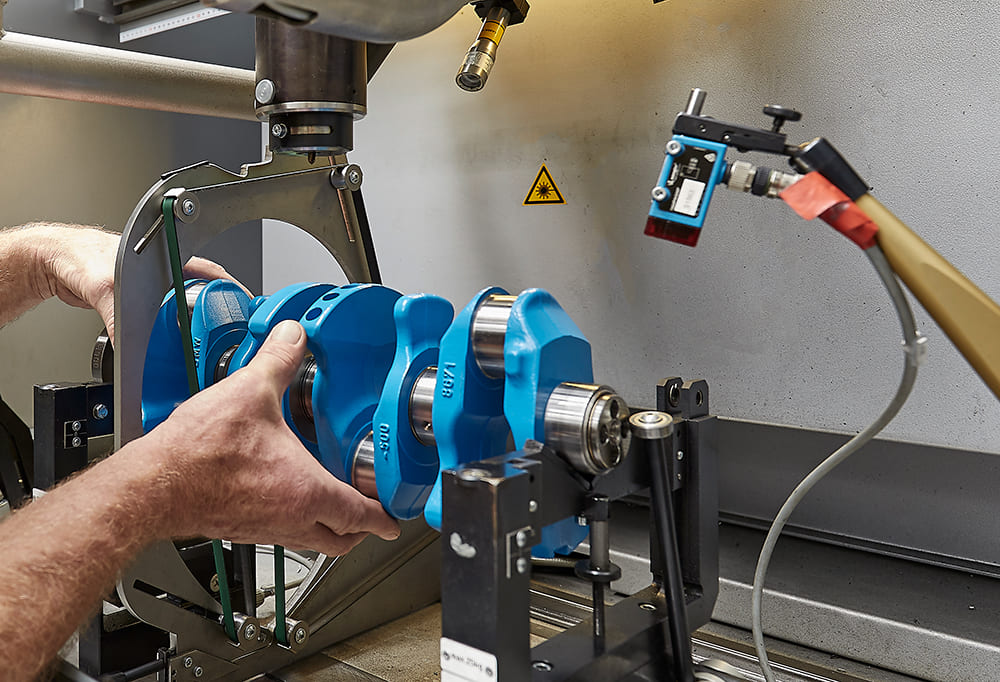

Mobile balancing with a portable balancing unit

On-site balancing is an essential process in many industrial applications, bringing machinery and equipment to their optimum balance. This process is vital to ensure that rotating parts such as motors, pumps, fans, generators and turbines work properly.

In many cases, rotors can be balanced directly on site with mobile balancing equipment. This saves you time-consuming disassembly work and the time-consuming transport of the rotor to a balancing machine. Often, satisfactory running behaviour can only be achieved with a "complete balancing" of the fully assembled rotor with all attached parts (fine balancing).

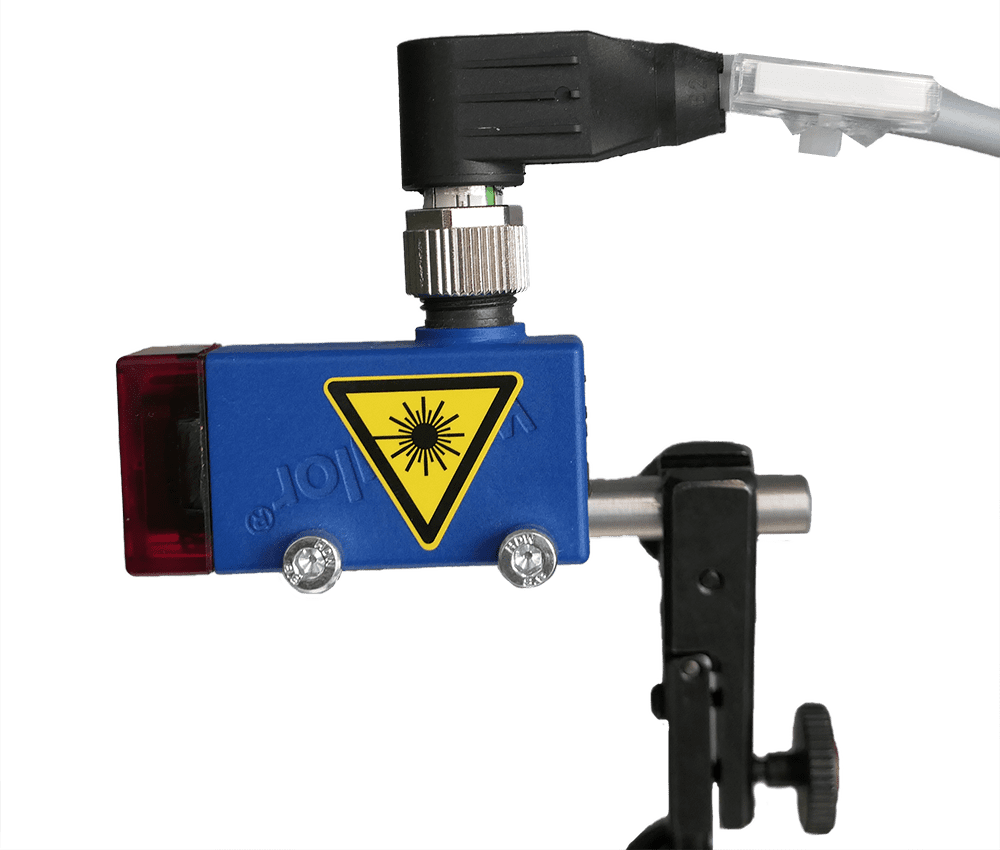

On-site balancing is carried out with the aid of special mobile balancing equipment, which determines the necessary balance weight according to mass and angular position.

Requirements for a successful on-site balancing service

- The machine must be able to run (several times) with the existing drive at constant speed during a measuring run.

- Accessibility of the rotor for the attachment of test and balance weights.

- Defined installation (fastening to the foundation or installation site).

So that everything runs smoothly for you

Our balancing service for you

Our experts understand the critical importance of balanced rotating components for the smooth operation of your machines. With us you will find specialised services designed to minimise vibrations and reduce wear on your rotating parts.

Our services

Precision balancing

Our experienced team uses advanced technology to ensure that your rotating parts are accurately balanced. This not only increases the life of your machines, but also improves overall efficiency.

Fast and efficient solutions

Our experts are trained to quickly understand your requirements and offer customised solutions. We minimise downtime and ensure that your machines are back in operation as soon as possible.

Quality and precision

We place the highest value on quality and precision at every step of our balancing service. Your satisfaction is our top priority.

Trust us to optimise the performance of your machinery and minimise downtime. Contact us today to learn more about how our rotating parts and machinery balancing service can meet your operational needs. We look forward to serving you with our expertise and commitment.

Our balancing service for you

Balancing rotating parts directly on site

An unbalance occurs when the mass of a rotating body is not evenly distributed around its point of rotation. This disturbs the equilibrium and results in an asymmetrical distribution of forces, which causes uneven rotation. There are various causes of unbalance, for example incorrect assembly or uneven material distribution. But wear over time can also lead to an imbalance.

To correct an unbalance, the causes must be identified and eliminated, for example by balancing the rotating body. We can determine this with the help of mobile balancing equipment.

Overall, on-site mobile balancing is a cost-efficient and effective way to improve the performance, safety and reliability of machinery and equipment. It helps to reduce downtime, lower operating costs and increase overall productivity, which is of great benefit in various industries.

Arrange a service appointment for balancing directly now!

Fast, simple & cost-efficient

Your advantages with mobile balancing

Increase safety

Balancing problems can be dangerous, especially in industrial environments. Unbalanced rotors can lead to uncontrolled vibrations and possibly serious accidents. Balancing reduces the risk of malfunctions and thus contributes to safety.

Reduce vibrations

Operational balancing minimises vibrations and shocks, resulting in smoother and more efficient machine operation. Reduced vibrations also mean less stress on the machine components, resulting in a longer service life.

Reduce noise

An out-of-round running component causes increased noise pollution due to vibration. This harms people who are in the vicinity of the end product or the machine. Smooth running can be restored by appropriate balancing.

Extending the service life

Proper balancing helps extend the life of machine components by loading them more evenly and reducing wear.

Energy efficiency

Balanced machines require less energy to deliver the same performance. This leads to improved energy efficiency and reduced operating costs.

Reduce maintenance costs

Unbalanced rotors can lead to premature wear of bearings, seals and other components. On-site balancing helps prevent these problems, which in turn reduces maintenance costs.

Other services

Vibration investigation

We are at your side from the very beginning. From identifying your vibration problems to setting the ideal vibration behaviour.

Laser optical alignment

Precise alignment of your entire machine park with modern laser-optical alignment work and special assemblies tailored to your requirements

We are happy to support you!

Make an appointment for balancing directly now.