Reliable and highly accurate measurement

Modules and software

for vibration monitoring of your machines

Put together your individual measuring system to improve the accuracy and availability of your machines.

How to get your readings

What is the function of vibration monitoring modules?

Vibration monitoring modules are devices or modules that are used to monitor and analyse vibrations in machines or systems. They are often used in industrial environments to detect early signs of mechanical problems or malfunctions that could lead to breakdowns or expensive repairs.

These modules typically record data such as the intensity, frequency and type of vibration. Through continuous monitoring, deviations from normal operating conditions can be quickly recognised. In this way, they enable operators to carry out preventive maintenance measures before serious damage occurs. Vibration monitoring modules therefore help to improve operational safety, reduce downtime and extend the service life of machines.

Advantages of vibration monitoring:

- Early error detection and correction

- Communication between machine, devices and computers via interfaces

- Improving the accuracy of the measured values

- Transmission and further processing of measured values

Overview of our measurement electronics

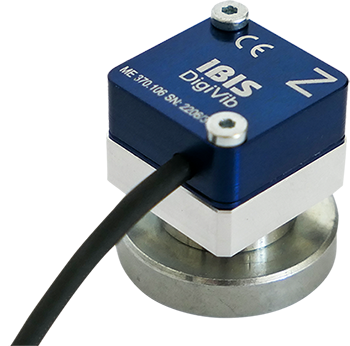

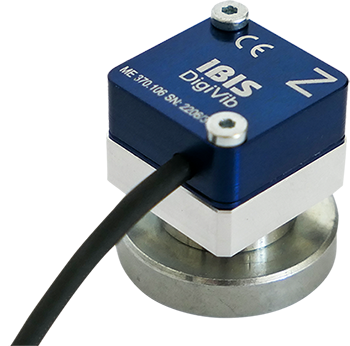

DigiVib vibration measurement system

DigiVib is a digital acceleration sensor with integrated microprocessor. The measurement takes place simultaneously in 3 axes with temperature and speed recording and direct evaluation on the PC.

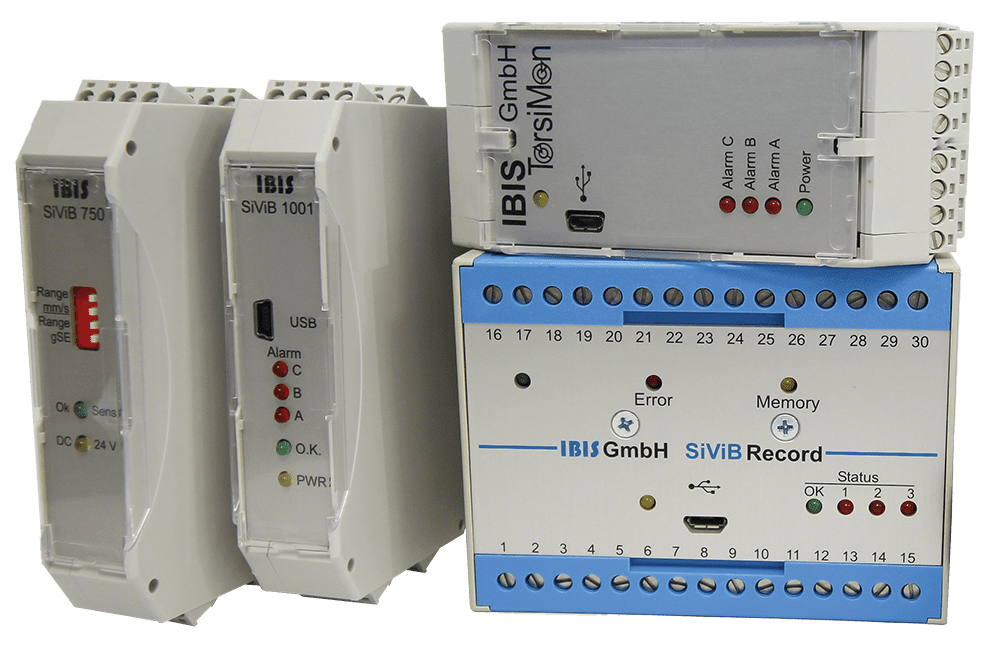

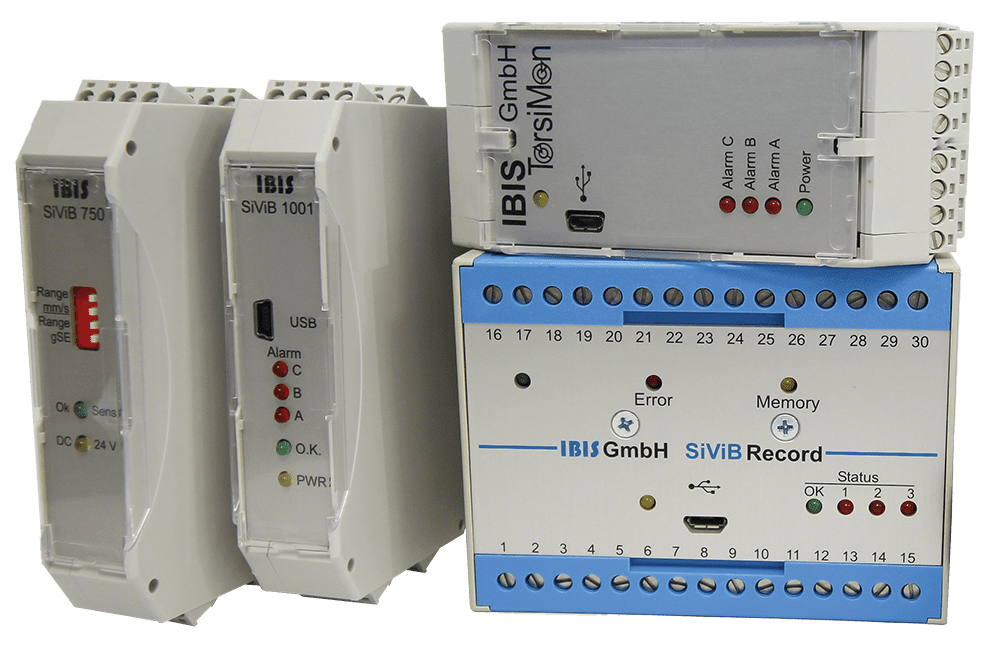

Vibration and rolling bearing monitor

Type SiViB

SiViB stands for comprehensive condition monitoring of vibration, rolling bearing condition, temperature, speed and other values. Internal measured value memory and interfaces for data transfer help with analysis.

Models:

SiViB 750

SiViB 1001

SiViB 1500

Record Control Software for SiViB

Configuration and analysis software for SiViB Record measurement modules

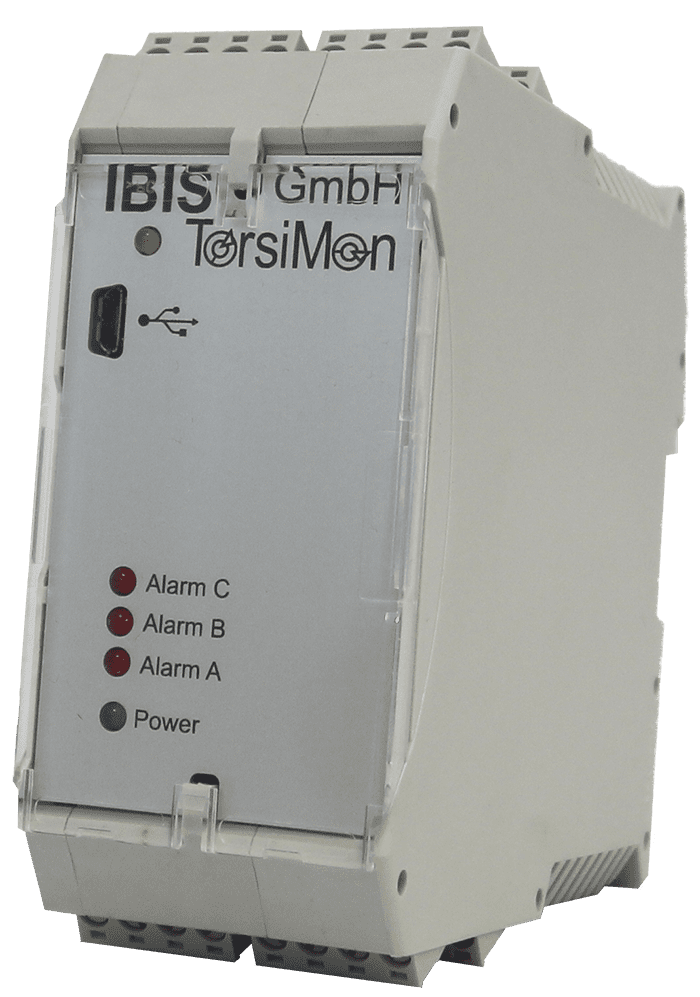

Surveillance monitor type TorsiMon

TorsiMon is used to monitor torsional vibration (rotational irregularity), torsional vibration, torsional angle and for subsequent torsional analysis on machines.

Portable measuring devices

Vibration monitoring with portable measuring devices

Vibration measurement and balancing on site

More about our portable measuring devices for vibration analysis and balancing from Hofmann Mess- und Auswuchttechnik.

Measuring physical quantities

Advantages of vibration monitoring

Vibration monitoring offers numerous advantages in various application areas. Here are some of the most important advantages of such monitoring systems:

Precision

Vibration monitoring enables precise and accurate measurements, which is crucial in many areas such as research, science and industry.

Speed

Electronic measurement techniques often provide faster measurement results compared to manual methods, which is especially important in real-time applications.

Data analysis

Electronic measuring devices can record and store data, which enables detailed measurement analysis and evaluation to make informed decisions.

Automation

Vibration monitoring modules can be integrated into automated machines, increasing efficiency and productivity by enabling continuous and reliable measurements without human intervention.

Cost efficiency

In the long term, metrology often offers greater cost efficiency by providing accurate and reliable measurements and reducing the need for repetitive manual measurements.

Flexibility

Electronic measuring devices can be adapted for different parameters and sizes, which increases their flexibility and adaptability to different measurement requirements.

More products

Sensors

So that no signal is lost. Discover the variety of our sensors for acceleration and vibration.

Portable measuring devices

Do you want even greater accuracy? Take a look at our portable measuring devices.

Do you still have questions about vibration monitoring?

Contact us! We will find the right solution for your application.