Highly accurate & precisely aligned

Laser optical alignment

of machines & plants

Achieve maximum accuracy and efficiency of your machines and equipment with Ibis Laser Optical Alignment.

Get the perfect laser-aligned machine

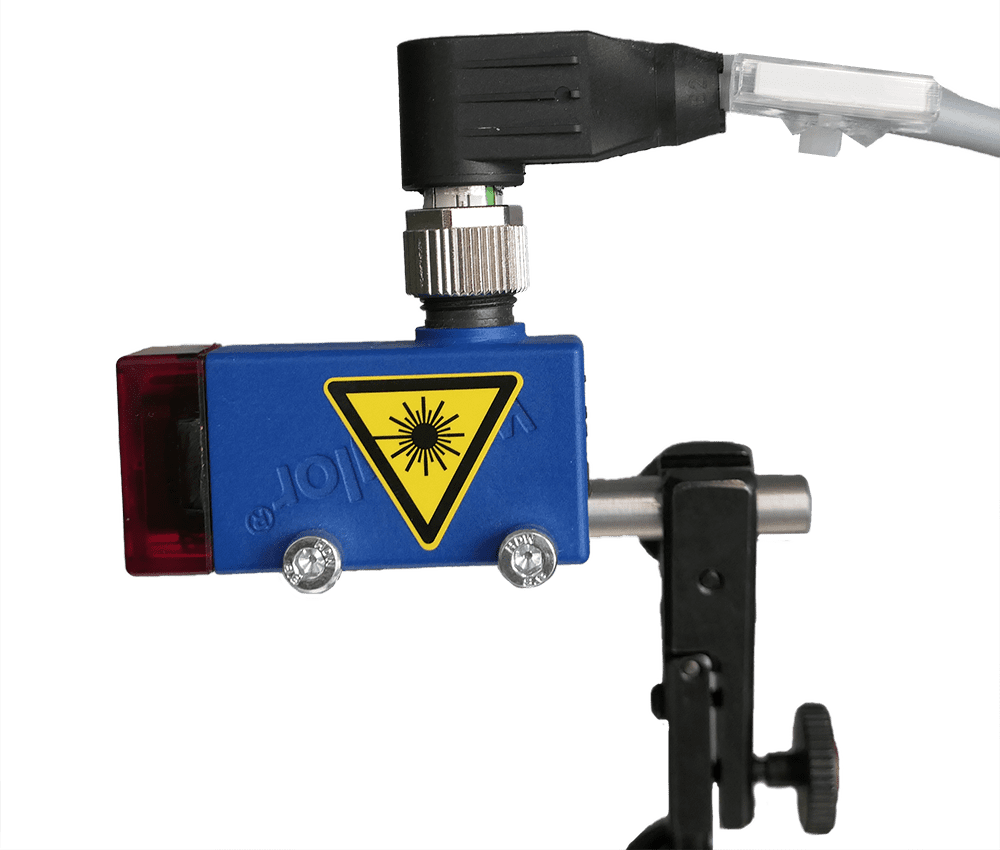

Aligning machines with laser technology

Machines often need to be aligned with each other to ensure smooth and trouble-free running. Aligning machines with laser technology is crucial to ensure efficiency, accuracy and longevity.

Nowadays, laser-optical alignment systems are state of the art. However, they are only worthwhile purchasing if they are used regularly. If you only have to perform alignment tasks occasionally, our service is the perfect alternative.

We align your machines using the latest laser technology and can also, if necessary, adjust the Balancing on site at the same time.

Fields of application of laser optical alignment:

- Unbalance in rotors that are difficult to balance.

- Resonance phenomena (at critical speeds).

- Chatter marks or other manufacturing problems.

Achieve precise results

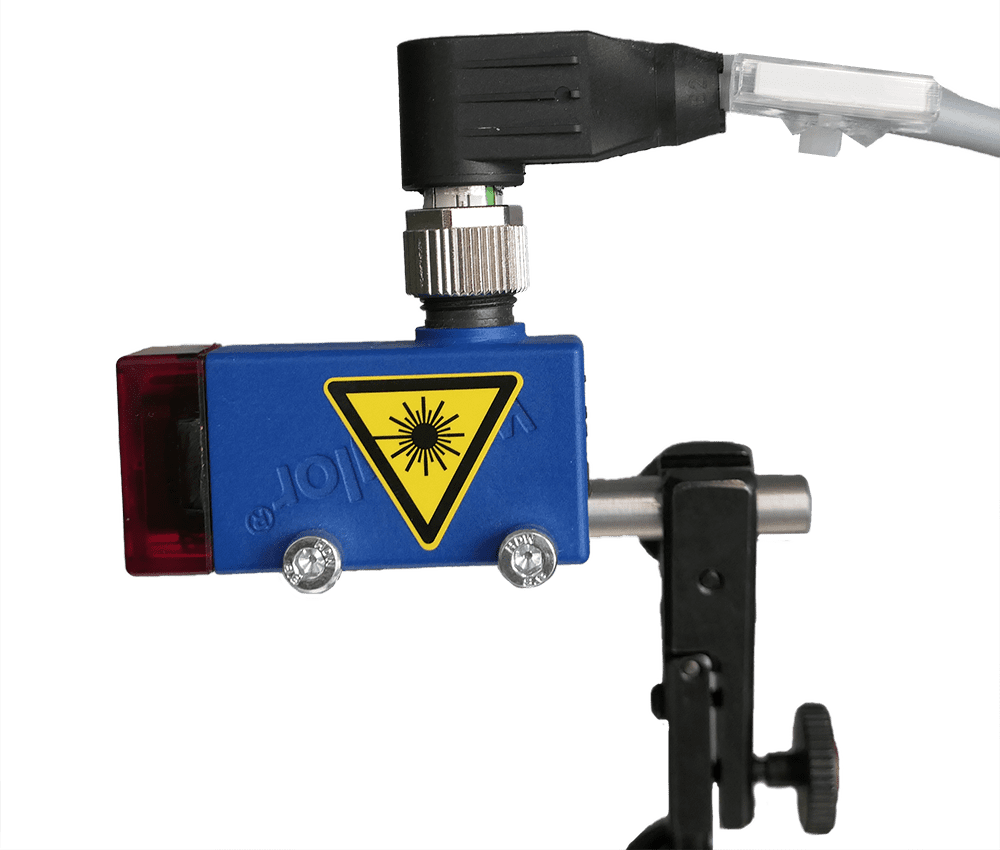

Special mounts for laser optical alignment

Before, during or after laser-optical alignment, special assembly work is often necessary to achieve the ideal position of your machines. With the help of our laser technology and experienced service personnel, we can support you in many areas of special assembly:

- All laser-optical alignment work that arises in the PST area.

- Shaft train assembly & disassembly, also in the high speed range.

- Runout & axial runout measurements.

- Assumption of or support with almost all assembly work in the PST area (special tools, fixture construction).

Make an appointment now for laser optical alignment of your machines!

Precision and efficiency

Advantages of laser optical alignment

Laser-optical alignment of machines is crucial to ensure the efficiency, accuracy and longevity of machines and equipment. Here are some important reasons why laser optical alignment is necessary:

Precision and accuracy

Laser optical alignment enables extremely precise and accurate adjustment of machine components. This is particularly important in industries where even minor deviations can lead to quality problems, production errors or wear.

Wear reduction

Precise alignment minimises unnecessary wear and premature abrasion on machine components. This leads to longer machine life and reduces the need for expensive repairs or spare parts.

Avoidance of downtime

Machines that are not properly aligned tend to fail more often. Laser optical alignment minimises downtime by significantly reducing the likelihood of machine failure due to alignment problems.

Increase in product quality

Precisely aligned machines produce higher quality products because they deliver consistent results. This is particularly important in the manufacturing industry, where product quality has a significant impact on market success.

Increase efficiency

Correctly aligned machines work more efficiently, resulting in lower energy consumption and lower operating costs. This is beneficial from both an economic and an ecological point of view.

Security

A precise, laser optically aligned machine minimises the risk of accidents and injuries that can be caused by poorly aligned machines.

Other services

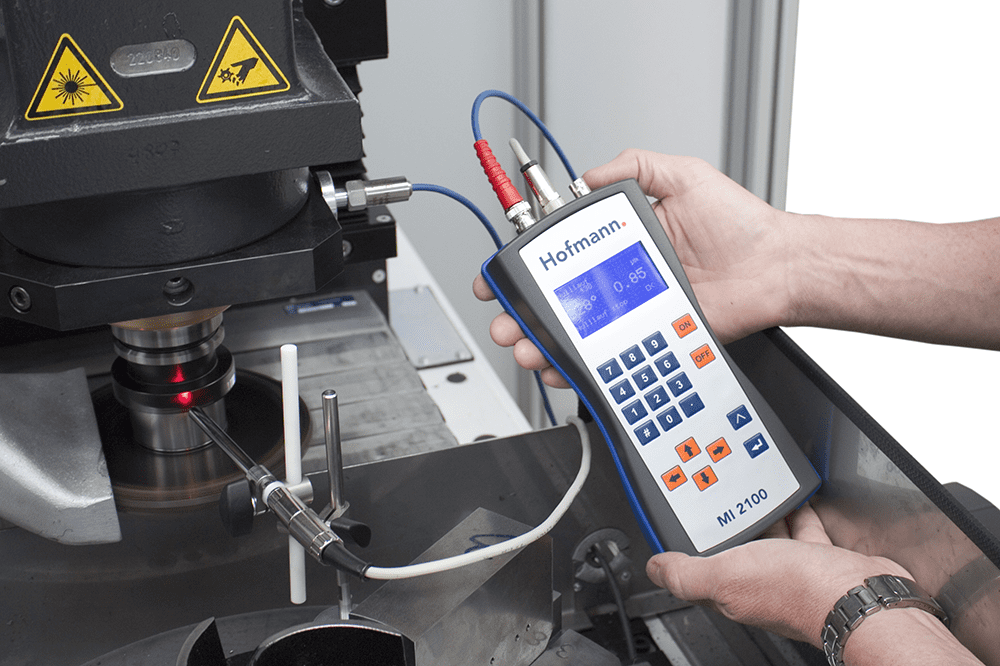

Balancing on site

We take over all balancing tasks for you quite conveniently with portable balancing equipment without high transport costs or time-consuming dismantling work.

Vibration investigation

We are at your side from the very beginning. From identifying your vibration problems to setting the ideal vibration behaviour.

We are happy to support you!

Make an appointment for laser optical alignment directly now.