Testing and measuring sensors

Sensor tester

for acceleration sensors

The sensor tester with fast and effective function check - so that you can always rely on the measurement results of your sensors.

Sensors » Sensor tester

Our solution for testing your sensors

Automatic test sequences with the sensor tester

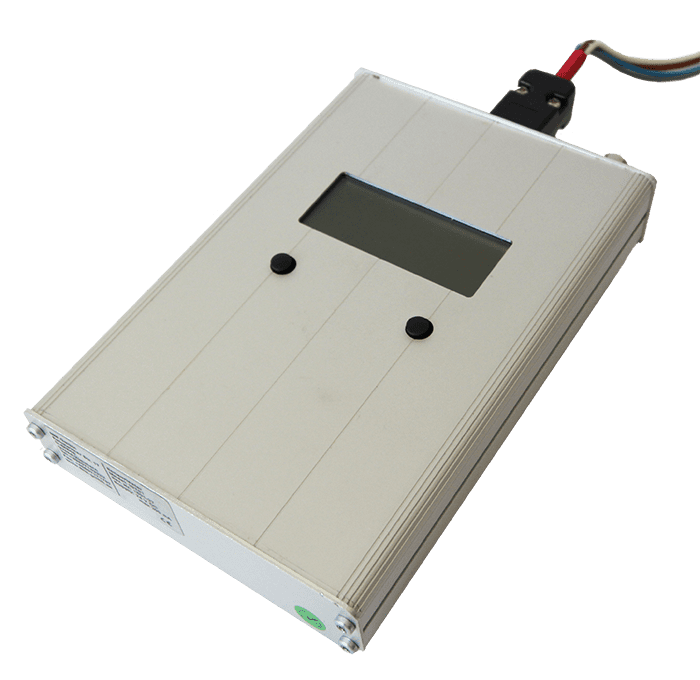

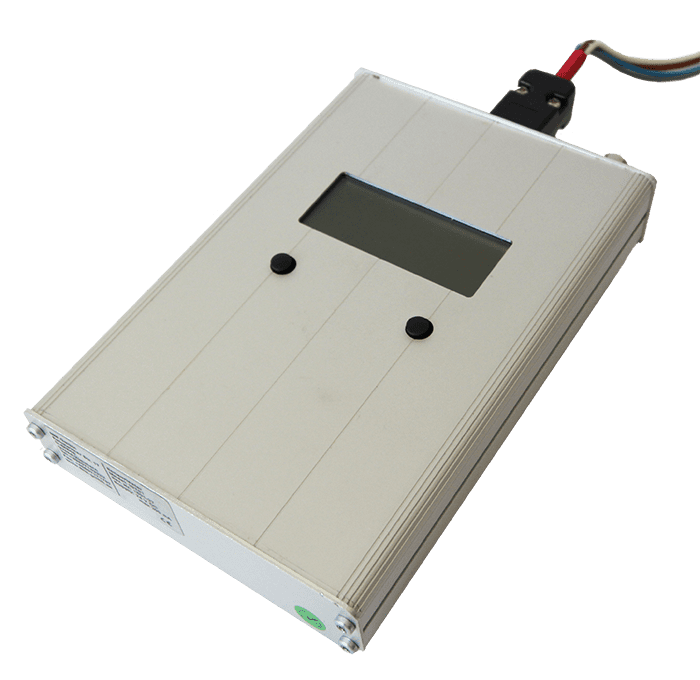

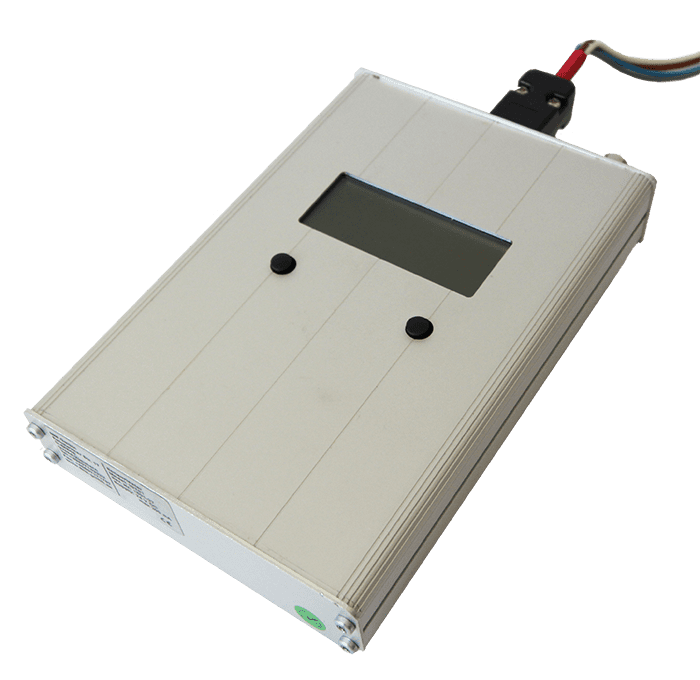

The sensor tester is designed for fast functional testing of acceleration sensors that operate according to the ICP principle. These sensors are supplied with a constant current, which is provided by the tester. The test procedure starts by pressing a button on the sensor tester. The tester automatically carries out the tests that make sense for the respective sensor type. The test result is shown with meaningful messages on the 4-line display of the sensor tester.

Simple operation for fast readings:

- Connection to suitable connection cable.

- Selection of sensor type and start of test run.

- Test for short circuit and then start the constant current supply element.

- Display of bias voltage and potential errors.

- Display of the vibration velocity.

- Checking the sensor sensitivity by means of defined vibration.

Overview of our sensor testers

Sensor tester type IST 01

Sensor tester for testing acceleration sensors with constant current supply, display and intuitive operation and evaluation of the measured values.

Testable sensors:

Type AE10 / 100

Type AI10 / 100

Type AM100

Type AR100

Maintenance & monitoring of machines

Advantages of sensor testers

Sensor testers help improve the reliability, efficiency and safety of machines, which in turn increases operational efficiency and reduces costs. They play an important role in the maintenance and monitoring of machines.

Flexibility and adaptability

Sensor testers can be adapted to different machine types and sensor types, allowing them to be used in a wide range of industries and applications.

Improved machine availability

By regularly checking and testing sensors, machines can stay in operation longer because problems are fixed before they lead to failures. This increases machine availability and boosts productivity.

Extended service life of machines

By identifying and fixing problems in a timely manner, machines can stay in operation longer, extending the overall life of the machines and reducing the need for expensive replacements.

Quality control

In certain manufacturing processes, sensors are crucial for quality assurance. Sensor testers help to ensure that these sensors are working correctly and thus guarantee the quality of the manufactured products.

Data collection and analysis

Sensor testers can collect data on the performance of machines and sensors. This data can be used to analyse and optimise operating processes to increase efficiency and reduce energy consumption.

Early fault detection

Sensor testers allow sensors to be monitored in real time. This allows potential problems to be detected at an early stage before they lead to serious failures. This helps minimise unplanned downtime.

Security

Sensor testers contribute to safety by ensuring that critical sensors function properly. This is especially important in safety-critical environments such as industry or transport.

Remote monitoring

Some sensor testers allow remote monitoring of sensors and machines. This is particularly useful in decentralised or difficult-to-access environments.

Reduced maintenance costs

Sensor testers help with preventive maintenance of machines. This makes it possible to carry out maintenance work in a more targeted manner and avoid unnecessary maintenance costs.

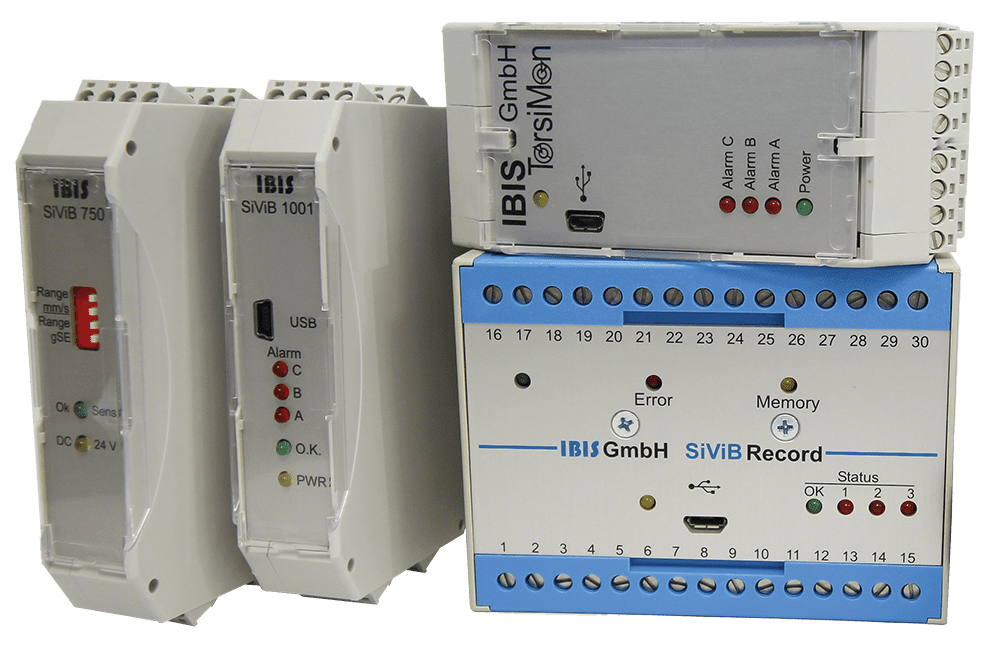

Matching products

Vibration monitoring

The perfect complement for your vibration analysis with sensors:

Complete your monitoring system with the appropriate vibration monitoring modules.

Sensors

With our sensors for vibration and acceleration measurement, you record precise movements and vibrations and optimise the performance of your machines.

Do you still have questions?

Contact us! We will find the right tool for your area of application.