Condition monitoring of machines

Vibration investigation & analysis

Vibration measurement, natural frequency analysis, torion analysis and many other applications - to ensure smooth operation.

Identify vibrations

Determining the cause through vibration investigation

Vibrations, due to unbalance and vibrations of the machine, usually lead to errors and disruptions in production. In the event of vibration problems, we carry out investigations to determine the cause of the vibrations and offer you a solution to rectify the fault.

There is a wide range of tasks that can be solved by a vibration investigation:

Typical tasks of vibration investigation:

- Unbalance correction for rotors that are difficult to balance.

- Resonance phenomena (at critical speeds).

- Chatter marks or other manufacturing problems.

- Self-excited vibrations during machining.

- Poor tool life due to vibration stress.

After completion of the vibration investigation, the vibrations are analysed. You will receive a report from us on the condition of the machine and the associated recommendation for any necessary measures.

Make an appointment for a vibration analysis now!

Vibration analysis

Our vibration investigation services at a glance

We accompany you from the very beginning of the vibration investigation. We make it possible to analyse the causes of unwanted vibrations and to take appropriate measures to reduce vibrations.

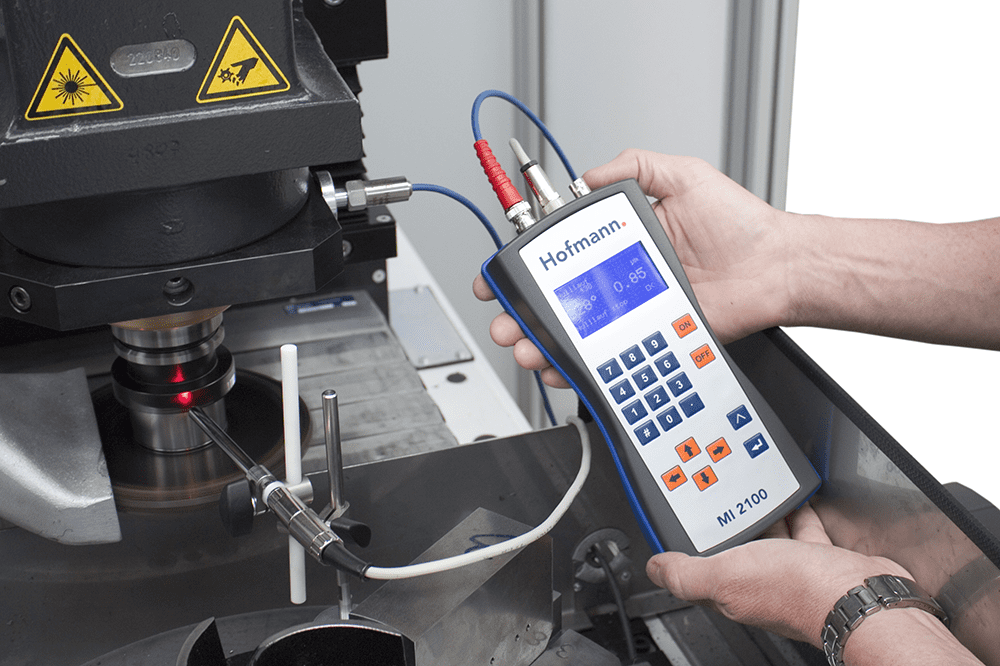

This could be, for example, the Balancing on site be. With the help of a mobile balancing device, we determine the position of the necessary balance weight according to mass and angular position and can thus reduce oscillations and vibrations.

Here you will find information on some of the methods we use to investigate vibrations:

Vibration analysis

- Measurement of various vibration behaviour parameters

- Optimisation or problem analysis on test bench shaft trains or other components

- Validation or optimisation of vibration calculations

- Vibration consulting / calculation / simulation

- Vibration acceptance measurements

Modal & Natural Frequency Analysis

- Determination of natural frequencies and natural modes

- Fourier analysis

- Resonance analysis

- Determination of the damping properties

- Evaluation and interpretation of the results and optimisation

Torsional analysis & torsional vibration measurement

- Definition of the initial conditions

- Calculation of the torsional stiffness

- Determination of stresses and deformations

- Evaluation of the torsional strength

A torsion analysis can be used, for example, in the design of drive shafts, propellers, crankshafts, turbine rotors.

Other services

Balancing on site

We take over all balancing tasks for you quite conveniently with portable balancing equipment without high transport costs or time-consuming dismantling work.

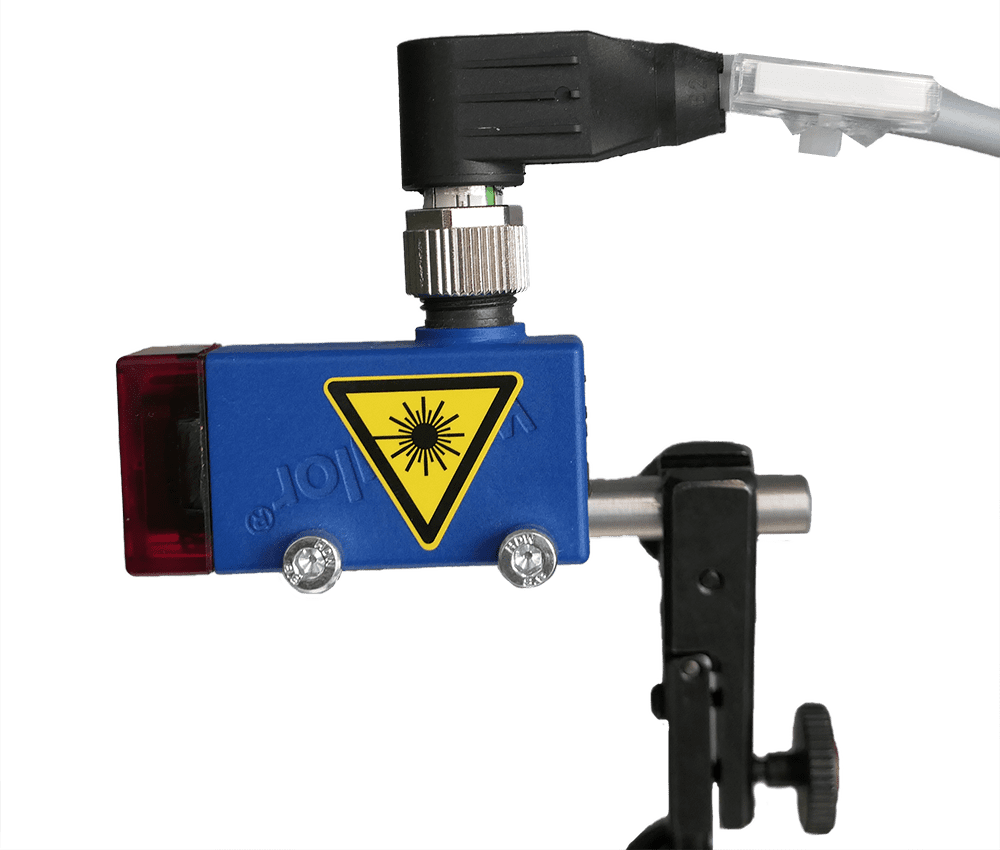

Laser optical alignment

Precise alignment of your entire machine park with state-of-the-art laser-optical measurements and special assemblies - tailored to your requirements.

We are happy to support you!

Make an appointment for vibration testing now.